Notícies

CENTRE DE NOTÍCIES

- Notícies de l'empresa

- Industry Express

-

Tecnologia de soldadura intel·ligent per a perfils d'alumini industrials d'EMU

La carrosseria del vehicle feta de materials de perfil d'alumini industrial té els avantatges de pes lleuger, resistència a la corrosió, bona aparença, planitud i materials reciclables, per la qual cosa és preferida per les empreses de transport urbà i els departaments de transport ferroviari de tot el món. Alumini industrial...

Veure més -

Com optimitzar el disseny de l'extrusió d'alumini per aconseguir una reducció de costos i una alta eficiència

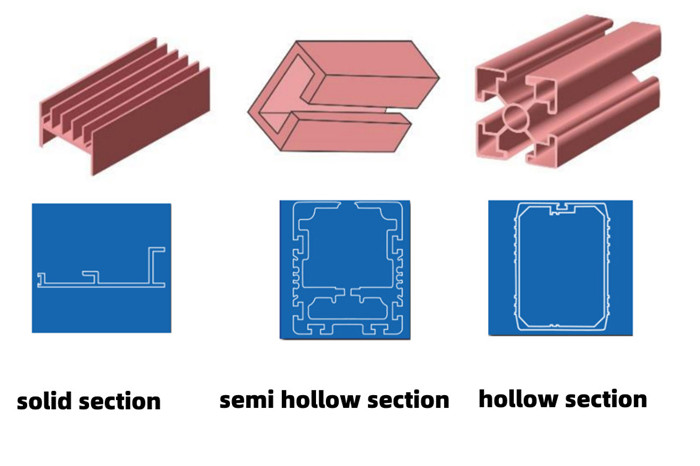

La secció d'extrusió d'alumini es divideix en tres categories: Secció sòlida: baix cost del producte, baix cost del motlle Secció semibuida: el motlle és fàcil de desgastar i trencar, amb un cost del producte i un cost del motlle elevats Secció buida: cost del producte i cost del motlle elevats, el cost del motlle més alt per a porus...

Veure més -

Goldman augmenta les previsions sobre l'alumini a causa de l'augment de la demanda xinesa i europea

▪ El banc diu que el metall tindrà una mitjana de 3.125 dòlars per tona aquest any ▪ Una major demanda podria "desencadenar preocupacions per l'escassetat", els bancs diuen que Goldman Sachs Group Inc. ha augmentat les seves previsions de preus per a l'alumini, dient que una major demanda a Europa i la Xina podria provocar escassetat de subministrament. El metall probablement tindrà una mitjana...

Veure més

-

Taula de fórmules de càlcul del pes de l'aliatge d'alumini

1. Verificació del principi físic de la fórmula bàsica Llei de conservació de la massa Totes les fórmules es basen en la naturalesa física de m=ρ×V (massa = densitat × volum) Valor de densitat Densitat teòrica de l'alumini pur: 2.698 kg/m³ (20℃) El valor aproximat de 2.700 kg/m³ és raonable per a...

Veure més -

L'estructura de l'aliatge 6082 abans i després de l'homogeneïtzació

1. Composició de l'aliatge 2. Procés d'homogeneïtzació 390 ℃ x aïllament durant 1,0 h + 575 ℃ x aïllament durant 8 h, refredament per vent fort a 200 ℃ i després refredament per aigua. 3. Estructura metal·logràfica (a) 50 × (b) 100 × Figura 1 Estructura metal·logràfica del nucli del lingot d'aliatge 6082, gravada mitjançant Keller rea...

Veure més -

Resum de coneixements sobre modificació de motlles i soldadura

1. Textura i color de cuir diferents, punts de soldadura Causa 1: El material de la zona de soldadura és diferent del material original. Mesures corresponents: utilitzeu filferro de soldadura que sigui coherent amb el material base, preferiblement filferro de soldadura especial utilitzat en fàbriques d'acer; en segon lloc, serrar el material...

Veure més